Bicycle components refer to the crankshaft positioner, pedals, handlebars, etc. connected to the frame. The titanium component industry is developing faster than the Ti-3AL-2.5V frame industry, and most of the components are produced with Ti-6Al-4V, Most of the parts are machined from bars or plates. The purchasing power of Ti-6A1-4V for parts is only 1/3 of that of Ti-3 gusset 2.5V frame, about 10t in 1997. Casting parts can become more and more common, but the development in this area may be slower than the development of machined parts. Titanium suppliers start to provide titanium parts manufacturers with cheap materials. Most of these low-cost bicycle-grade materials are actually Obsolete aviation materials.

The material requirements of the bicycle frame are very simple, but the driving characteristics are particularly critical, which complicates the selection of materials in some aspects. Most transportation vehicles, structural elements and internal facilities and operating elements are separated. Until recently, all bicycles The frame requires structural integrity and suspension function. There is no titanium alloy specially designed for bicycles. Only some materials have been improved for bicycles. Most people consider cost reduction issues and accept titanium components. The main problem is rigidity rather than cost. Ti-3Al-2.5V is the most commonly used titanium alloy for bicycles. Although it is developed for aircraft hydraulic systems, it is due to formability and corrosion resistance. The high fatigue strength to weight ratio and good elongation makes it meet the bicycle market performance standards. Compared with other titanium alloys, the biggest advantage of Ti-3Al-2.5V is the yield strength and easy tube forming. The disadvantage is its price and mold. The ratio of volume to density is poor. It is not easy to extrude Ti-3Al-2.5V as the dominant frame material. Ti-6AI-4V also has a certain attraction, and its modulus and strength are better than Ti- 3Al-2.5V is higher, but it is difficult to process into a tube with a small diameter like a bicycle frame. Ti-15V-3Al-6Cr-4Mo-4Zr is also easy to shape, but its higher density and lower modulus offset its strength The improved advantages.

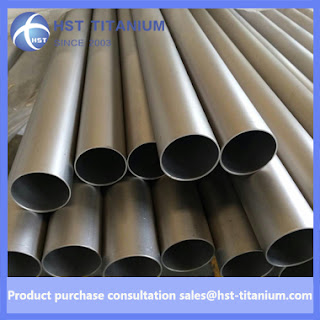

Grade 7 Titanium Bar titanium alloy tube thin titanium plate titanium block